RIVET

Because there is effectively a head on each end of an installed rivet, it can support tension loads (loads parallel to the axis of the shaft); however, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft). Bolts and screws are better suited for tension applications.

Fastenings used in traditional wooden boat building, like copper nails and clinch bolts, work on the same principle as the rivet but were in use long before the term rivet came about and, where they are remembered, are usually classified among the nails and bolts respectively.

Types of riveted joints and joint efficiency:

Riveted joints are mainly of two types

1. Lap joints

2. Butt joints

Lap Joints: The plates that are to be joined are brought face to face such that an overlap exists,Rivets are inserted on the overlapping portion. Single or multiple rows of rivets are used to give strength to the joint. Depending upon the number of rows the riveted joints may be classified as single riveted lap joint, double or triple riveted lap joint etc. When multiple joints are used, the arrangement of rivets between two neighbouring rows may be of two kinds. In chain riveting the adjacent rows have rivets in the same transverse line. In zig-zag riveting, on the other hand, the adjascent rows of rivets are staggered.

Riveted joints are mainly of two types

1. Lap joints

2. Butt joints

Lap Joints: The plates that are to be joined are brought face to face such that an overlap exists,Rivets are inserted on the overlapping portion. Single or multiple rows of rivets are used to give strength to the joint. Depending upon the number of rows the riveted joints may be classified as single riveted lap joint, double or triple riveted lap joint etc. When multiple joints are used, the arrangement of rivets between two neighbouring rows may be of two kinds. In chain riveting the adjacent rows have rivets in the same transverse line. In zig-zag riveting, on the other hand, the adjascent rows of rivets are staggered.

In this type of joint, the lates are brought to each other without forming

any overlap. Riveted joint are formed between each of the plates and one or two cover plates.Depending upon the number of cover plates the butt joints Like lap joints, the arrangement of the rivets may be of may be single strap or double strap butt joints. various kinds, namely, single row, double or triple chain or zigzag. The strength of a rivet joint is measured by its efficiency. The efficiency of a joint is defined as the ratio between the strength of a riveted joint to the strength of an unrivetted joints or a solid plate. Obviously, the efficiency of the riveted joint not only depends upon the size and the strength of the individual rivets but also on the overall arrangement and the type of joints.

Important terms used in riveted joints:

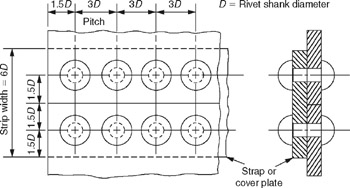

a) Pitch: This is the distance between two centers of the consecutive rivets in a single row. (usual symbol p)

b) Back Pitch: This is the shortest distance between two successive rows in a multiple riveted joint. (usual symbol pt or pb )

c) Diagonal pitch: This is the distance between the centers of rivets in adjacent rows of zigzag riveted joint. (usual symbol pd )

d) Margin or marginal pitch: This is the distance between the centre of the rivet hole to the nearest edge of the plate. (usual symbol m)

08:58

08:58

ramkesh

ramkesh

Posted in:

Posted in:

1 comments:

I want to share a testimony on how Le_Meridian funding service helped me with loan of 2,000,000.00 USD to finance my marijuana farm project , I'm very grateful and i promised to share this legit funding company to anyone looking for way to expand his or her business project.the company is funding company. Anyone seeking for finance support should contact them on lfdsloans@outlook.com Or lfdsloans@lemeridianfds.com Mr Benjamin is also on whatsapp 1-989-394-3740 to make things easy for any applicant.

Post a Comment